Shed installation service - Shop

Shed installation.. IS NOW AVAILABLE:

All Scooter Stores come with full instructions and are designed to be home assembly. You may however, choose the Scooter Stores, shed installation service to save you the time and effort of assembling yourself. Whichever decision you make, please read the following advice.

Before taking delivery of your new metal shed:

Before taking delivery, we recommend that all Scooter Stores are situated on a firm, flat, level base. Ideally this should be 50mm concrete, tarmac or flagstones (patio). You will notice all of the products on this website site have a "base size" this is the minimum level base size we feel is appropriate for each product. a firm, flat base will ensure doors open cleanly and will make assembly of the units much easier (Why is a level base important). Here is a quick reference list of recommended shed base sizes for each shed.

Shed base sizes

Before building your shed, it is important to make sure you have a good, firm base for your shed to sit on. Your shed should sit on a level base of either concrete, tarmac or paving slabs.

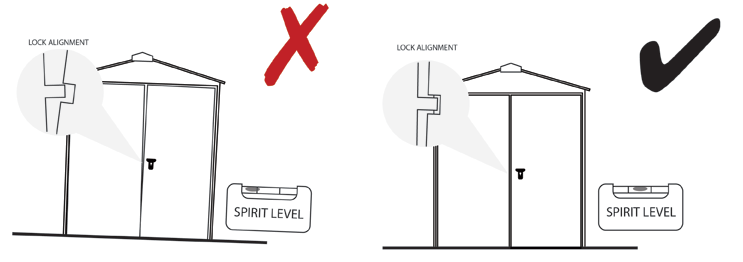

Why does the base have to be level? A common question! Sheds are precision made products – Designed to be as secure as possible – So the doors need to be level for all the bolts and locks to line up correctly and provide you with that top level of security famous for. The sheds are the heaviest on the market, with sheds weighing over 76 stone you need a decent base just to take the weight!

Products In This Category:

Metal shed - Self Assembly:

Our products are high quality, heavy gauge steel. As a result, all our metal storage is very heavy! Ensure you are physically able to construct such items before commencing work. Self assembly is straight forward, requiring 2 people (for most units) and a minimum of tools.

Ensure you have the correct tools and wear the appropriate safety equipment when trying to assemble the unit.

Ensure there is a good solid base for the metal shed to sit on.

Asgard accept no responsibility for loss, damage or injury resulting from building an Asgard unit.

Please note that it is the responsibility of the customer to ensure there is an adequate base for their shed, which must be solid, level tarmac, slabs or concrete (min 2 inches thick).

Securit GB Ltd can not be held responsible for unwanted units once delivered. A minimum 30% admin charge will be applied if we have to collect the unit. This is subject to our standard terms and conditions.If you choose to cancel your order, you must ensure the goods are returned to us in a saleable condition. If the unit has become damaged in your possession you may be charged up to 90% of the original order value.

Planning Permission:

Securit Gb Ltd sheds do not normally require planning permission. However, there may be exceptions such as in a conservation area or in certain London boroughs. The customer must check with the relevant authorities prior to ordering their unit. Asgard will take no responsibility if after taking delivery a customer is asked remove the unit due to local authority regulations.

Why does the shed base need to be bigger than the shed?

Metal sheds feature an integral metal base so can be bolted down to a concrete base as an added security measure. If the shed base is built to the exact size of the shed and you attempt to bolt the shed down, the impact of the drill can cause the concrete below to break and crumble.

*Please note if you wish to secure/drill your optional ground anchor to the floor you will require a minimum 100mm depth of concrete. Tarmac and paving stones are not suitable. We do not fit or supply ground anchors.

Shed installation instructions:

Please contact our sales team and we can email you a copy.

Our optional installation service includes:

Panel by panel inspection - To make sure the product is in perfect condition before assembly.

Full assembly - quickly and efficiently - this will include additional water proofing of all joints with silicone compound.

Anchoring - Drilling of holes and anchoring of the unit to your base.

Inspection- Final visual inspection of the product for defects or problems.